Available in strip

During the production process of strip and coil, the edge of the material develops a sharp edge, commonly referred to as a burr. This sharp edge has both safety and manufacturing implications. The burr poses a potential health and safety hazard, and the material can be more difficult to work with, increasing manufacturing time and ultimately costs. Edge Dressing helps minimise these risks and provides a cost effective and safe solution to manufacturers.

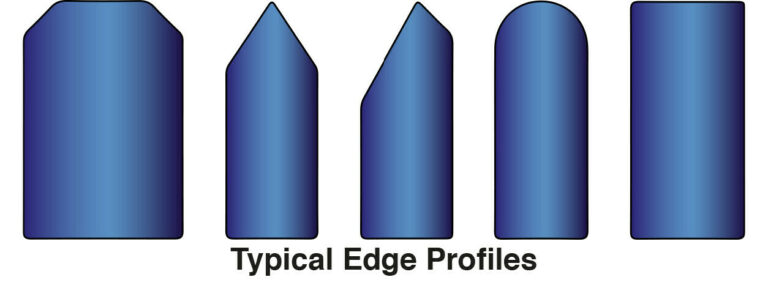

The Knight Group offers manufacturers the flexibility to choose the processing that meets your needs, and we can supply material edge-dressed to your specifications. Whether you need the commonly requested rounded or square edge shapes or you need a contoured edge shape tailored specifically to you, we offer the Edge Dressing profile you need. We design and use Bespoke Tungsten Carbide Tooling to meet the most exacting Custom Edge Dressing requirements on Precision Strip.

With the heavy investment in our bespoke machinery and a wealth of experience in our team, our machines can offer precision processing in high volumes with fast turnaround times.

Edge Dressing

| Edge Type | Width Range (mm) | Width Range (inches) | Thickness Range (mm) | Thickness Range (inches) |

|---|---|---|---|---|

| De-burred Safe | 4.5 – 110 | 0.18 – 4.33 | 0.15 – 3.0 | 0.006 – 0.118 |

| Fully Rounded | 4.5 – 110 | 0.18 – 4.33 | 0.15 – 2.0 | 0.006 – 0.080 |

| Dressed Square | 7.0 – 80 | 0.28 – 3.15 | 0.15 – 2.0 | 0.006 – 0.080 |

| Chamfered | 10.0 – 80 | 0.39 – 3.15 | 0.30 – 2.0 | 0.012 – 0.080 |

| Rolled Round | 8.0 – 75 | 0.32 – 2.95 | 0.80 – 3.50 | 0.032 – 0.138 |

Edge Profiling Size Range (mm)

Specified Thickness (mm): From | Up To | Width <19 |

|---|---|---|

| 0.1 | 0.25 | ± 0.10 |

| 0.25 | 0.5 | ± 0.12 |

| 0.5 | 1 | ± 0.15 |

5 Edge Finishing Lines

Bespoke Tungsten Carbide Tooling

Simple de-burring

Rounded Edges

Chamfered Edges

Square Edges

Available in: Pancake Coils or Spools

Some applications that require edge dressed rounded or profiled strip

Flexible Hoses, Pressings, Banding, Precision Strip, Electronic Components, Tube Strip, Exposed Plated edges, Shock Absorber Strip, Automotive Exhausts, Automotive Trim, Heating Element Strip, Cotter Pins, Tools, Weaving Loom Applications, Band Saw Strip, Medical Blades, Springs, Tolerance Rings

All data is provided for informational purposes only. In no event will the Knight Group and its subsidiaries, be liable for in respect of any action taken by any third party arising from using the information taken from our online or printed sources. Chemical and Mechanical Properties should not be construed as maximum or minimum values for specifications, nor should information be used to assess suitability for a particular use or application. The information and data provided is deemed to be accurate to the best of our knowledge and may be revised anytime without notice and assume no duty to update